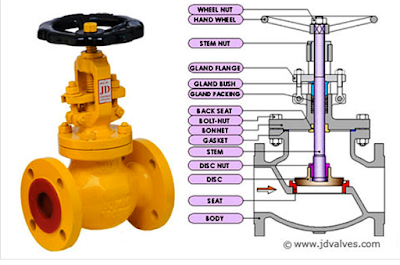

Globe Control Valve Parts, Principle, Types

Globe Control Valve

A shell and tube money dealer|device} could be a category of warmth exchange styles.

It is the foremost common form of device in oil refineries and alternative giant chemical processes, and is suited to higher-pressure applications.

As its name implies, this sort of warmth money handler consists of a shell (a giant pressure vessel) with a bundle of tubes within it

Shell and tube device represent the foremost wide used vehicle for the transfer of warmth in process applications. they're ofttimes chosen for such duties as:

method liquid or gas cooling

method or refrigerant vapor or steam condensation

method liquid, steam or refrigerant evaporation

method heat removal and preheating of feed water

Thermal energy conservation efforts, heat recovery

Compressor, rotary engine and engine cooling, oil and jacket water

Hydraulic and fill oil cooling

several alternative industrial applications

Layouts

Shell and tube (a.k.a. multi pass) device AR the foremost common industrial application for liquid/liquid heat exchange.

Inside the shell, baffles (dividers) AR put in to direct the flow round the tubes, increase speed, and promote cross flow. They additionally facilitate support the tubes. The baffle cut is that the quantitative relation of the baffle window height to the shell diameter. Typically, baffle cut is concerning twenty p.c.. Designers additionally ought to specify the baffle spacing; most spacing depends on what proportion support the tubes would like.

A pass is once liquid flows all the method across from one finish to the opposite of the money handler. we'll count shell passes and tube passes. associate degree money handler with one shell pass and 2 tube passes could be a 1-2 money handler . since odd numbers of tube passes have a lot of sophisticated mechanical stresses, etc. associate degree exception: 1-1 exchanges AR typically used for vaporizers and condensers.

How do I decide whether or not the given shell and tube device could be a counter flow or parallel flow?

If the recent fluid is flowing in same direction as of cold fluid, then it's parallel device.

Bur if the recent fluid is flowing in direction opposite to the cold fluid then it's counter flow device.

2) If you have got the data concerning the temperatures at body of water and outlet condition then you'll resolve the effectiveness. If the effectiveness is a smaller amount than five hundredth it's principally parallel flow heat ex hanger. however if it's over five hundredth than it's counter flow as effectiveness of parallel flow can not be over five hundredth. If each have effectiveness but five hundredth then the larger one is counter flow device.

3) If there AR 2 heat exchanges before of you with same parameters like body of water and outlet temperatures, mass rate. If you have got to make a decision that one is parallel and counter flow,then the warmth money handler with larger space are going to be parallel flow whereas the one with less space are going to be counter-flow device.

4) If the outlet temperature of the recent fluid is a smaller amount than outlet temperature of cold fluid it's undoubtedly counterfoil heat exchange because it is feasible solely in counter-flow device

5) If you discover out the LTD of each heat ex changers for same mass flow rate, space then the one with higher LTD are going to be counter flow device.

This article gave me such a valuable insight into the world of industrial valves! The breakdown of different valve types and materials used was incredibly helpful. If anyone's curious to know about top Globe Valves Supplier. check out valvulasfevisa.com.Thanks to the author for making this complex topic so accessible!

ReplyDelete