Distributed Control Systems (DCS) Information

Distributed Control Systems (DCS) Information

Distribute management systems (DCS) use decentralised components or subsystems to regulate distributed processes or producing systems. they provide flexibility, extended instrumentation life, simplicity of recent instrumentation integration, ANd centralized maintenance once employed in an industrial atmosphere.

Characteristics and style

A distributed system involves the location of multiple controllers at intervals a plant or producing method. The controllers square measure networked to a central console. DCSs aim to concentrate plant operations to permit management, monitoring, and coverage of individual elements and processes at one location.

Components

DCSs square measure by definition ranked systems, though not all systems share a consistent hierarchy.

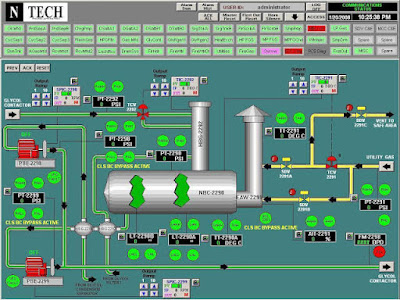

Theimage below shows a typical DCS. Individual controllers, supervised by master controllers, compose rock bottom "field" or "plant" level of the hierarchy. The master controllers hook up with individual computers and servers, that square measure more connected to video output devices and somebody's machine interface (HMI), that is that the actual purpose of user management. DCSs square measure typically networked exploitation normal protocols like PROFIBUS and local area network, the latter of that is employed during this explicit system.

It is vital to notice that a lot of DCS elements may also operate as standalone devices. whereas a DCS ultimately governs the practicality of its networked elements, constant elements will usually be reprogrammed to be used in alternative applications.

The design of DCS:

Distribution management Systems (DCS) consists of 3 major qualities.

1) numerous management functions may be distributed into little sets of subsystems that square measure of semiautonomous. These square measure interconnected by a high-speed communication bus and their functions embrace knowledge presentation, knowledge acquisition, method management, method oversight, coverage info, storing and retrieval of knowledge.

2) The second characteristic is that the automation of producing method by group action advanced management methods.

Features:

Distribution management Systems (DCS) may be employed in numerous management applications with a lot of range of I/O’s with dedicated controllers. These systems square measure employed in producing methodes wherever planning of multiple product in multiple procedures such a batch process management.

Features of DCS are:

• System redundancy

• a lot of subtle HMI

• ascendible platform

• System security

Applications:

Distributed management systems (DCS) square measure majorly employed in producing processes that square measure continuous or batch-oriented.

Applicationsof DCS include:

• Chemical plants

• organic compound (oil) and refineries

• Pulp and Paper Mills

• Boiler controls and power station systems

• atomic power plants

• Environmental management systems

• Water management systems

• Water treatment plants

• biodegradable pollution treatment plants

• Food and food process

• Agrochemical and plant food

• Metal and mines

• Automobile producing

• metallurgic method plants

• Pharmaceutical producing

• Sugar processing plants

• Agriculture Applications

Benefits of exploitation DCS include:

It needs token troubleshooting

• It contains HMI graphics and faceplates

• Alarms

• Lends itself to raised organization and consistency than a PLC/HMI jazz group

• Batch management is feasible

• OPC server

• Reduced engineering time

• Redundant operator system servers

Redundancy

Most distributed management systems square measure designed with redundant components. Redundant engineering will increase a system's dependableness by exploitation backup processors just in case of primary processor failure. Redundant components square measure necessary in DCSs as a result of for 2 main reasons:

several DCSs management safety-critical processes within which failure or outage of apparatus might cause personal injury or loss of life. A oil refinery may be a example of safety-critical plant. In such AN atmosphere, an impression system governs flares that perpetually burn gas. If the system fails and also the flares stop burning, gas collects and pools, inflicting a particularly dangerous state of affairs.

Redundancy will increase instrumentation dependableness, deed the DCS operator to target displays, software, and applications. as a result of DCS systems need near-constant operator interaction at the HMI, redundancy is crucial.

Applications

Distributed management systems square measure most often employed in batch-oriented or continuous method operations, like oil processing, power generation, organic compound producing, trade, food and nutrient producing, pharmaceutical production, and cement process. DCSs might management any of variety of various instrumentation sorts, including:

Variable speed drives

internal control systems

control centers (MCC)

Kilns

producing instrumentation

Mining instrumentation

Relationship with PLCs and SCADA

Programmable Logic Controller

DCSs and programmable logic controllers (PLC) were traditionally employed in dissimilar applications, however this distinction has blurred a lot of recently. In fact, PLC

and DCS architectures square measure usually troublesome to tell apart and use several of constant elements, together with field sensors, I/O modules, HMIs, and superior management systems. Distributed management systems square measure generally way more high-ticket and management continuous processes and important applications, whereas PLCs square measure used for high-speed machine management.

No comments